Fractional distillation

The basic refinery uses fractional distillation. Incoming crude is heated to its

boiling point. It then enters the distillation column, which separates the

different fractions. The column is of the reflux type, where colder condensed

fluids running down are reheated by rising vapors that in turn condense. This

produces clear thermal zones where the different products can be drained.

NOTE: The schematic on the following page is simplified. Both continuous

and vacuum distillation is used in separate columns to avoid heating the raw

crude to more than 370 °C. Overheating would cause thermal cracking and

excessive coke that may also plug pipes and vessels. Also a sidecut stripper

is used, in addition to the main column, to further improve separation.

Sidecut is another name for the fractions emerging from the side (rather than

top and bottom) of the main column, i.e., naphtha, gasoline, kerosene and

diesel.

The fractions are a mix of alkanes and aromatics and other hydrocarbons, so

there is not a linear and uniformly rising relationship between carbon number

and boiling point and density, although there is a rough fit. Even so, this

means that each fraction contains a distribution of carbon numbers and

hydrocarbons.

78

6.2 Basic products

The basic products from fractional distillation are:

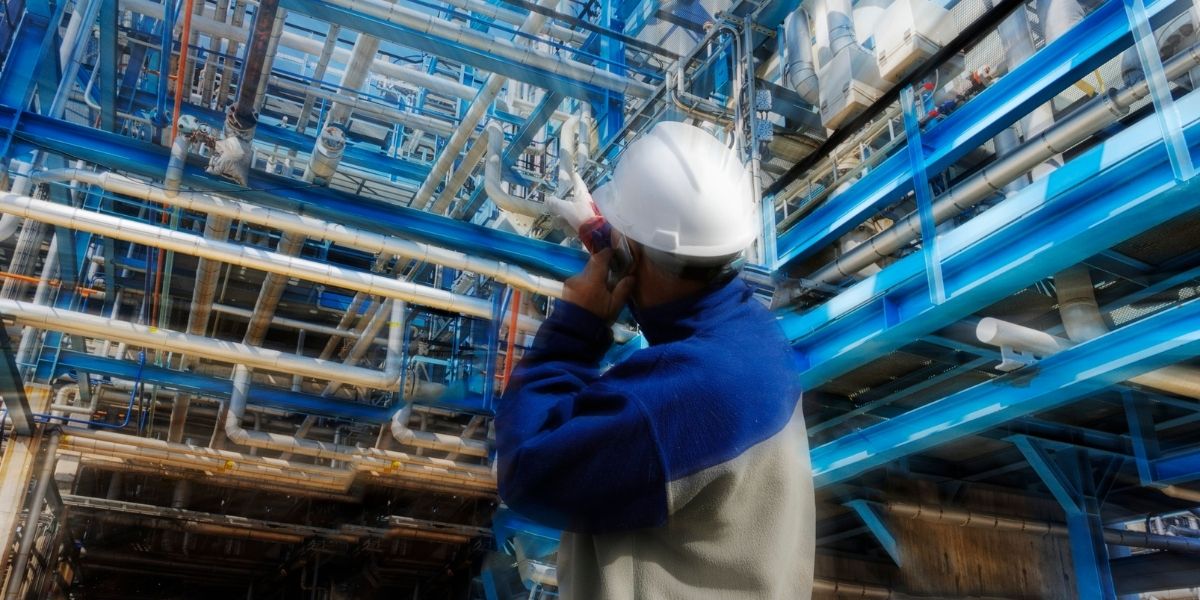

Figure 19. Fractionating continuous distillation, overview

Liquid petroleum gas (LPG) has carbon numbers of 1-5 and a boiling point

up to 20 °C. Most of the LPGs are propane and butane, with carbon number

79

3 and 4 and boiling points -42 °C and -1 °C, respectively. Typical usage is

domestic and camping gas, LPG vehicles and petrochemical feedstock.

Naphtha, or full range naphtha, is the fraction with boiling points between

30 °C and 200 °C and molecules generally having carbon numbers 5 to 12.

The fraction is typically 15–30% of crude oil by weight. It is used mainly as a

feedstock for other processes:

• In the refinery for producing additives for high octane gasoline

• A diluent for transporting very heavy crude

• Feedstock to the petrochemical olefins chain

• Feedstock for many other chemicals

• As a solvent in cleaning

Gasoline has carbon numbers mainly between 4 and 12 and boiling points

up to 120 °C. Its main use is as fuel for internal combustion engines. Early

on, this fraction could be sold directly as gasoline for cars, but today’s

engines require more precisely formulated fuel, so less than 20% of

gasoline at the pump is the raw gasoline fraction. Additional sources are

needed to meet the demand, and additives are required to control such

parameters as octane rating and volatility. Also, other sources such as

bioethanol may be added, up to about 5%.

Kerosene has main carbon numbers 10 to 16 (range 6 to 16) boiling

between 150 °C and 275 °C. Its main use is as aviation fuel, where the best

known blend is Jet A-1. Kerosene is also used for lighting (paraffin lamps)

and heating.

Diesel oil, or petrodiesel, is used for diesel engines in cars, trucks, ships,

trains and utility machinery. It has a carbon number range of 8 to 21 (mainly

16-20) and is the fraction that boils between 200 °C and 350 °C.

White and black oils: The above products are often called white oils, and

the fractions are generally available from the atmospheric distillation

column. The remaining fraction below are the black oils, which must be

further separated by vacuum distillation due to the temperature restriction of

heating raw crude to no more than 370-380 °C. This allows the lighter

fractions to boil off at a lower temperatures than with atmospheric

distillation, avoiding overheating.

Lubricating oils, or mineral base lubricating oil (as opposed to synthetic

lubricants), form the basis for lubricating waxes and polishes. These

typically contain 90% raw material with carbon numbers from 20 to 50 and a

80

fraction boiling at 300-600 °C. 10% additives are used to control lubricant

properties, such as viscosity.

Fuel oils is a common term encompassing a wide range of fuels that also

includes forms of kerosene and diesel, as well as the heavy fuel oil and

bunker that is produced at the low end of the column before bitumen and

coke residues. Fuel oil is graded on a scale of 1 to 6 where grade

1 and 2 is

similar to kerosene and diesel, 3 is rarely used anymore. 4-6 are the heavy

fuels, also called Bunker A, B and C, where B and C are very high viscosity

at normal ambient temperatures and requires preheating to about 100 °C

and 120 °C respectively, before it flows enough to be used in an engine or

burner. Fuel oil grade 4 does not require preheating and is sometimes mixed

with off spec products, such as tank residue and interface liquid from

multiphase pipelines or with grade 2 fuel oil to achieve low-enough viscosity

at ambient temperatures. Fuel oil 6 is the lowest grade, its specification also

allows 2% water and 0.5% mineral soil and is consumed almost exclusively

by large ships in international waters, where pollutants such as sulfur is less

regulated.

Bitumen and other residues like coke and tar has carbon numbers above 70

and boiling points above 525 °C. Low sulfur coke can be used for anodes in

the metals industry (aluminum and steel) after processing (calcining). The

remainder is a problem fuel, because of high sulfur content and even higher

CO2 emissions than coal (typically 15% higher). Bitumen in the form of

asphalt boiling above 525 °C is used for roofing and road paving. Asphalt

concrete pavement material is commonly composed of 5% asphalt/bitumen

and 95% stone, sand, and gravel (aggregates).

6.3 Upgrading and advanced processes

The Refinery make up differs from an upstream plant, in that the overall site

is divided up in to process types or 'units'. The refining plant type processes

are generally licensed, and a license is required to build and operate one of

these. Each license will be the same but scaled to meet the processing

capacity in tons per day. A full explanation of these processes is beyond the

scope of this book, but a non-exhaustive description is given below.

The following figure gives a more detailed process flow diagram of an actual

modern refinery. It shows the extent of treatment that takes place after initial

fractional distillation, to improve fuel yield and functional properties, and an

explanation of why modern gasoline at the pump contains less than 20% raw

gasoline straight from the column. Additional processes may also be

included, e.g., for crude pre-treatment to be able to source lower quality

crudes with less processing at the production site.

0 Comments